- Home

- Products

- Articles

- 4 Axis Robot Arm

- A Stepper Motor Driven Ferris Wheel (Version 3 Compiler required)

- An Update on Keith Cameron's Lift

- Automatic Tram Layout

- Bug in Increment Word Instruction

- Compiler Version Releases

- Industrial Arc Welding Robot

- MotorVating the Speed Play Robot

- Reproducing the Electronic Set Models

- Sensor Expansion Port Pinout Diagram

- Sheet 1 - Hardware from NZ 240 volt wall socket to...

- Sheet 3 Meccano Car model controlled by the MotorVator and Director.

- Sheet 2 - Hardware from Motor(s) to MotorVator®.

- User Input Options

- Version 3 Manual Released

- 16/32 Bit Maths Routines

- Build Your Own Photo Sensor

- Controlling Stepper Motors

- Magnetic reed switch as a non contact sensor

- MeccCompiler III Tutorial

- More Inputs and/or Motors: Port Replication

- More Inputs: the Sensor Expansion Port

- Square Root Function

- Tutorial: Rev Counter

- Use of the opto switch or opto interrupter as a ro...

- FAQ

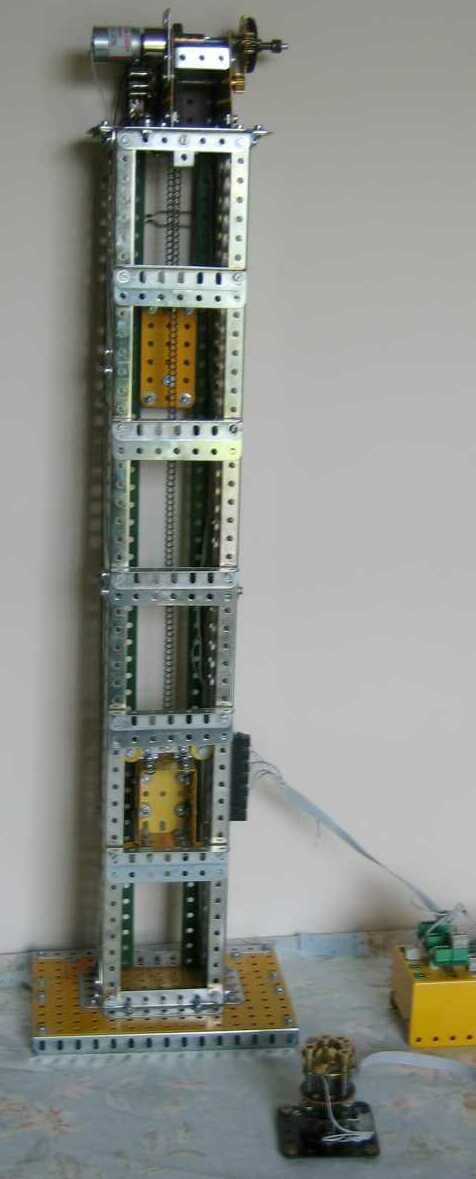

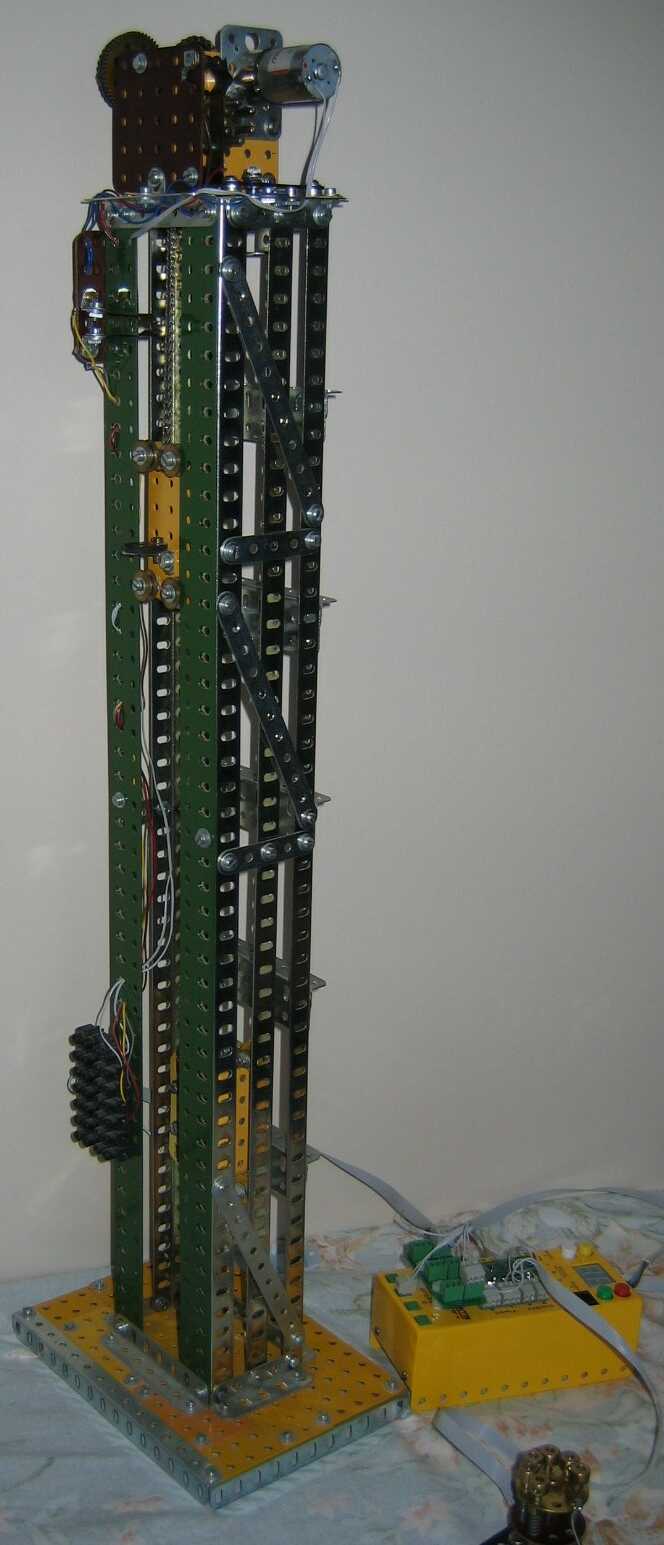

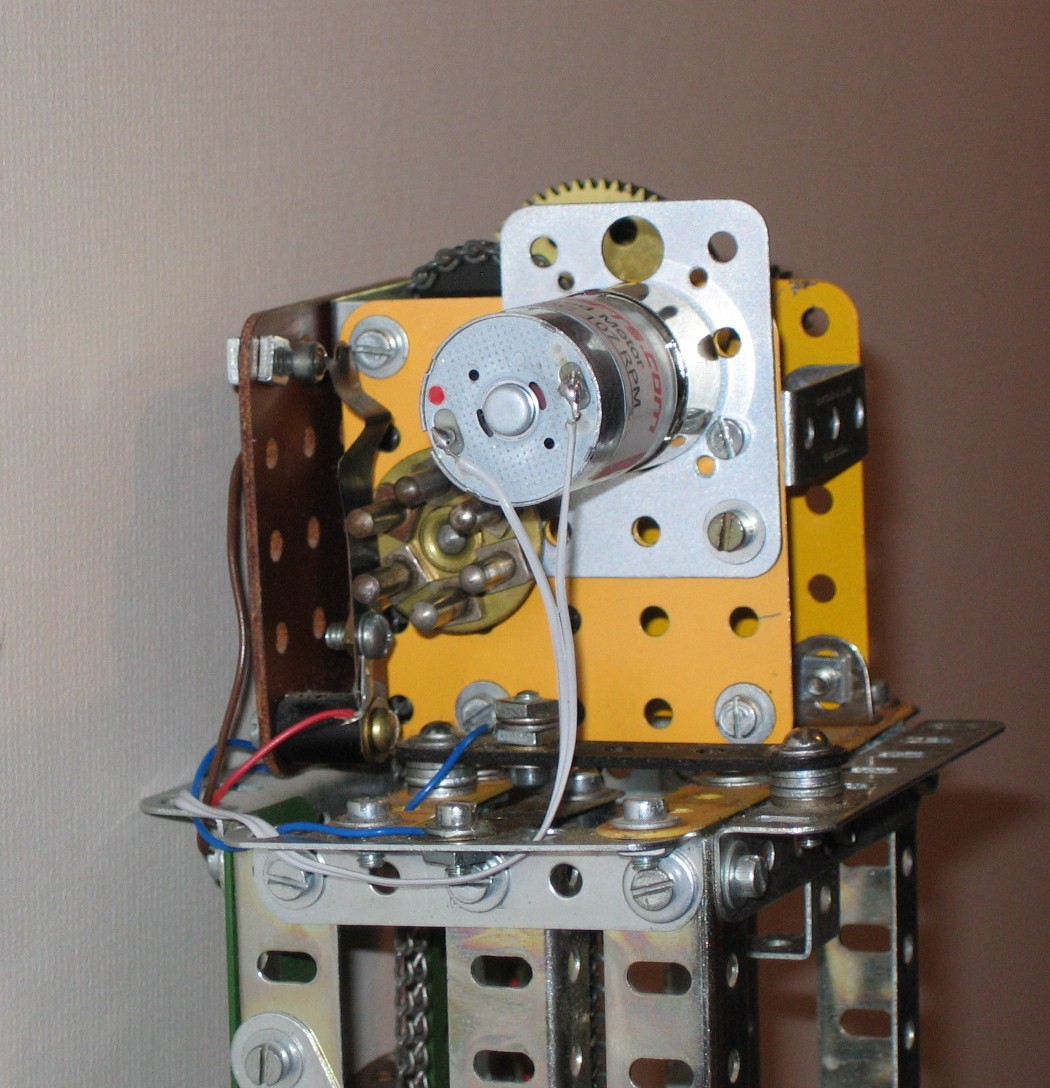

An Update on Keith Cameron's Lift

The Model is based on a design by Keith Cameron published in Constructor quartely No 7 march 1990 and is a simple example of the application of the Motorvator. This really complements my tram model as in the latter case this was an example of how the Motorvator could considerably simplify the automatic operation of a model without user intervention, whereas the lift model demonstrates how the Motorvator can considerably simplify a model requiring user intervention. I have seen a lift model wth a very complex circuit involving numerous relays to do the same job.

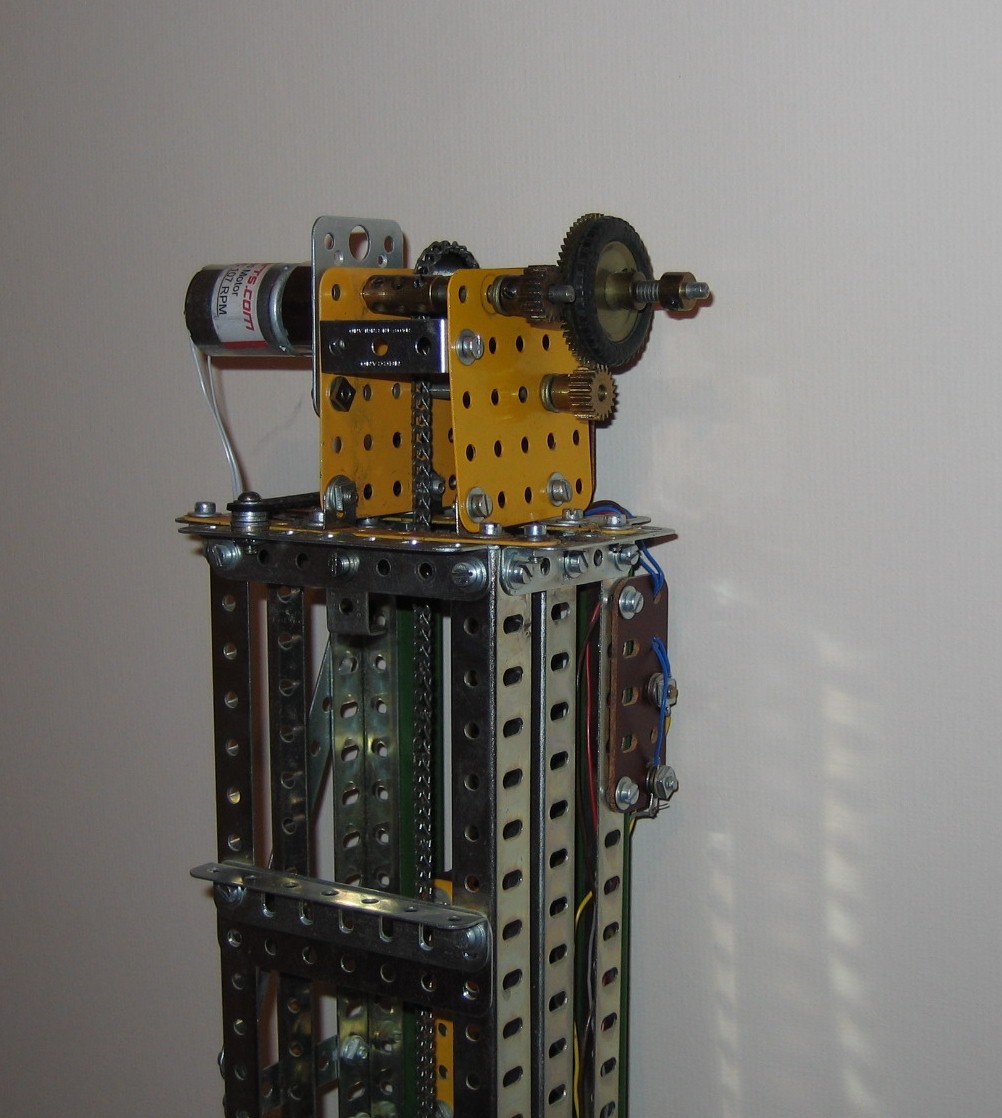

The model is accurate at floor levels to about +- 3mm max.and more usually to +- 2mm. It might be possible to improve on this with further tweaking. The problems are motor overrun , positioning of the rotation counter when it stops and possibly the rotation counter missing a pulse ( I don't think this happens although it might). I have used a Meccanisms 107rpm motor which seems just right for the job. Of course a stepper would give exact positioning and I might modify the model to test this.

On the model, selecting ground or 5th floor will re register the position and can always be selected if a sgnificant position error is noticed although in practice I have rarely found an error greater than 4mm. Andrew has suggested that greater accuracy might be obtained by slowing the motor to reduce overun as the lift approaches floor level and I am experimenting with this.

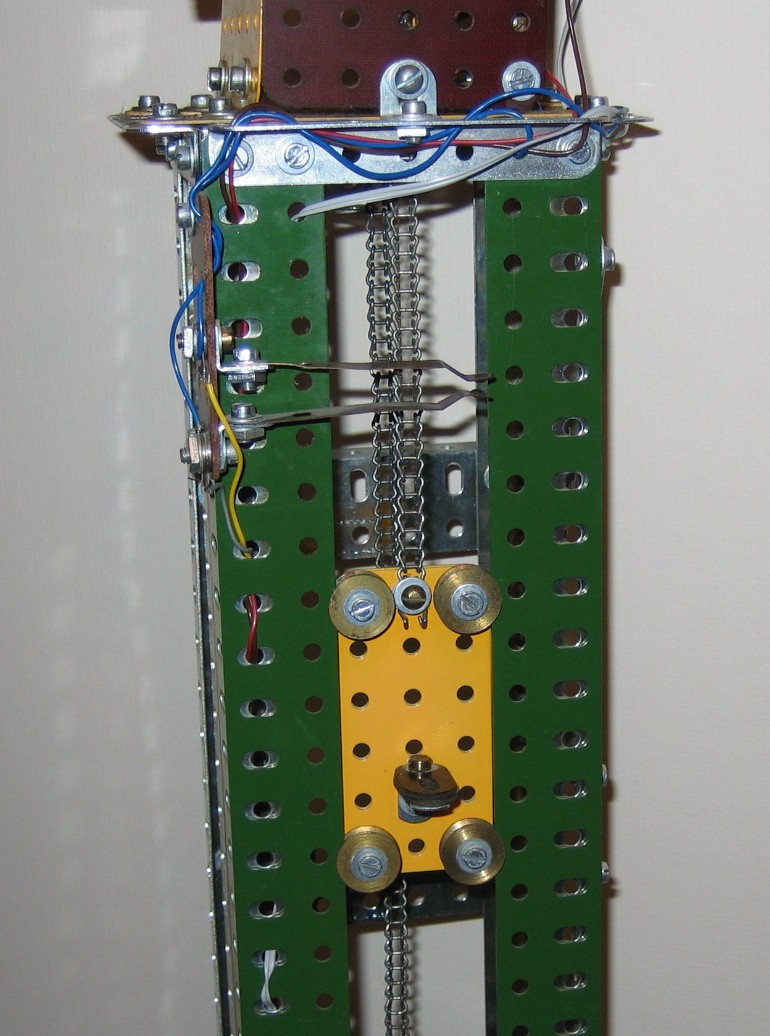

Note that the limit switch in the photo IS the ground floor switch: it is triggered by the counterweight which is of course at the top when the lift car is at the bottom!

The Consul of lift call buttons is made of standard Meccano and Electrikit parts. the connection to the motorvator is to OnOff 1(two wires), OnOff 2 to 4 (+ive pin only), Timed 1 (centre pin only) and timed 2 (centre pin only). The ground is connected at the consul to all 6 inputs.

The inputs from the model are the rotation counter connected by two wires to Timed 4 (ground and centre signal pins), the limit switch for ground and fifth (two switches one connection to timed 3) and the motor connected to motor port B.

I have used the Director socket extension board but I imagine that the Analogue inputs on the Motorvator could be used instead with a small change in the program.

As you can see the program consists of a simple loop which tests for a button press for each floor in turn.

The Consul could be considered as a model specific "Director" and the idea could be extended to much more complex models.

Here is the code for the MotorVator

Begin Program

Declare Byte Counter=0

Declare Byte Totalcount=0

Declare Byte Stoptb=0

Declare Byte Ground=0

Declare Byte First=0

Declare Byte Second=0

Declare Byte Third=0

Declare Byte Fourth=0

declare Byte Fifth=0

Declare Byte DiffCount=0

Declare Byte StartCount=0

Declare Byte Finalcount=0

Declare Byte AtFloor=0

Declare Byte Speed=50

Disable Events

SetEvent 19,rotationcount

Enable Events

Call Initialise() ;This initialises the program and takes the lift to the Ground floor

Loop

ground=readOnOff(1)

if ground=1 then

AtFloor=0 ;This variable prevents any action if the lift is already at the floor for the button pressed

Call Initialise() ;also reregisters position

end if

first=readOnOff(2)

if AtFloor<>1 then

if first=1 then

call GoToFirst()

Atfloor=1

end if

end if

second=readOnOff(3)

if second=1 then

if AtFloor<>2 then

Call GoToSecond()

AtFloor=2

end if

end if

third=readOnOff(4)

if third=1 then

if AtFloor<>3 then

Call GoToThird()

AtFloor=3

end if

end if

fourth=readtimedstate(1)

if fourth=1 then

if AtFloor<>4 then

Call GoToFourth()

AtFloor=4

end if

end if

fifth=Readtimedstate(2)

if fifth=1 then

Call GoToFifth() ;Also reregisters position

AtFloor=5

end if

End Loop

End Program

Declare EventHandler RotationCount()

counter=ReadTimedState(4)

If counter=1 then

TotalCount=TotalCount+1

End If

DisplayNumber Totalcount

End EventHandler

Declare Function Initialise()

SetMotor 2,backward,speed

Do

stoptb=readtimedstate(3)

Until stoptb=1

Do

SetMotor 2,backward,speed

counter=ReadTimedState(4)

Until counter=0

Stopmotors

totalcount=0

End Function

Declare Function

GoToFifth()

SetMotor 2,Forward,speed

Do

Stoptb=readtimedstate(3)

Until Stoptb=1

;displayNumber totalcount

Do

counter=1 ; An attempt to move the counter to a standard position

displayNumber counter

SetMotor 2,forward,speed

counter=ReadTimedState(4)

displayNumber counter

Until counter=0

Stopmotors

totalcount=120

stoptb=0

End Function

Declare Function

GoToFirst()

If TotalCount<=24 then

Do

SetMotor 2, forward,speed

Until totalcount=26

totalcount=24

End If

If TotalCount>24 then

StartCount=totalcount

Do

SetMotor 2, backward,speed

DiffCount=Startcount-totalcount ;calculates the position relative to the last count

finalcount=Startcount+DiffCount

Until finalcount=30

TotalCount=24

End If

StopMotors

End

Function

Declare Function

GoToSecond()

If TotalCount<=48 then

Do

SetMotor 2, forward,speed

Until totalcount=48

End If

If TotalCount>48 then

StartCount=totalcount

Do

SetMotor 2, backward,speed

DiffCount=Startcount-totalcount

finalcount=Startcount+DiffCount

Until finalcount=53 ;In an ideal world this would be 48 but changes were made to allow for motor overun.

TotalCount=48

End If

StopMotors

End Function

Declare Function

GoToThird()

If TotalCount<=72 then

Do

SetMotor 2, forward,speed

Until totalcount=72

End If

If TotalCount>72 then

StartCount=totalcount

Do

SetMotor 2, backward,speed

DiffCount=Startcount-totalcount

finalcount=Startcount+DiffCount

Until finalcount=76 ;see note above

Totalcount=72

End If

StopMotors

End Function

Declare Function

GoToFourth()

If TotalCount<=96 then

Do

SetMotor 2, forward,speed

Until totalcount=96

End If

If TotalCount>96 then

StartCount=totalcount

Do

SetMotor 2, backward,speed

DiffCount=Startcount-totalcount

finalcount=Startcount+DiffCount

DisplayNumber finalcount

Until finalcount=101

End If

TotalCount=96

StopMotors

End Function